Safety valves are essential to the protection of lives and property. they are Installed on process equipment to release excess pressure, due to upset process operations, external fires and other hazards. failure of pressure safety valves to function properly when needed, could result in the over-pressure of vessels, exchangers, boilers or other equipment they were installed to protect, so periodic testing is crucial to ensure that valves are in a good condition, functioning properly and will provide the so important protection. But can you really be sure of the results if the test is not conducted under the stress of everyday conditions? Unsurpassed for accuracy, reliability and safety, the advanced technology of AccuTEST was developed to test the function, set pressure and general performance of your spring operated safety valves under a full load, for consistently superior, reproducible results. while in position without interrupting the process operation, The valve stays online; This means the valve is accurately tested in its process conditions.

Utilizing the industry’s most advanced software, this fully automated system virtually eliminates the possibility of human error. From automatic calibration of sensors to output of the final test results, the totally computerized operation delivers superior performance with regard to set-up, ease of use, accuracy and reporting.

Please see video : https://www.youtube.com/watch?v=5CVWtvrCsG4

Pressure safety valve in normal operation condition is subjected to 2 types of force, the 1st is line pressure, the second is a result of spring tension keeping the valve closed and tight.

When The airplane aluminum test bracket is adapted to the valve size and positioned on to the spring operated safety valve, and during the test, hence the valve is subjected to 3 types of force, the 1st is line pressure, the second is a result of spring tension keeping the valve closed and tight, and the third is the proportional rising force created by the AccuTEST system bringing the valve to the cracking point(set pressure).

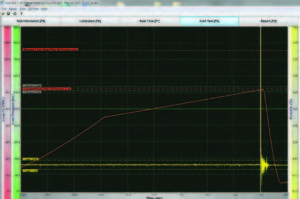

The set pressure is the moment the disc commences to lift, the test detect this point by the lift acoustic and force sensors.

The corresponding measured values used in the automatic set pressure calculations.

Set Pressure=Line Pressure+(Pulling Force/Valve Seat Area)

Advantages

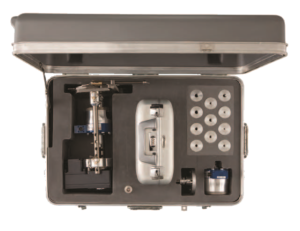

- Universal mounting assembly ensures use on all types of exposed spindle valves, from all major manufacturers.

- Full range of valve spindle adapter sets available in English or Metric, coarse and fine threads.

- No hydraulics, cylinders or hand jack.

- Totally automated operation produces accurate, consistent, reproducible results within all ASME codes.

- Quickly identifies problem valves; diagnoses incorrect set pressures by measuring lift force, line pressure and acoustic lift signature.

- Titanium and aluminum rig is lightweight and portable.

- 15.24m (50′) control cable connects electronics case to load rig.

- Portable, easy on-site setup.

- Integrated database of valve specifications from all major valve manufacturers.

- Enter new valves into database as needed.

- Eliminates need to over-pressurize, take equipment offline or remove welded-in valve.

- Lift force generated by computer-controlled, battery-operated electric motor.

- Battery life for two days of typical testing.

- Temperature compensated load and pressure sensors provide wide range of valve sizes and line pressures.

- Standard load rig allows for lift forces up to 4,500 kgs (10,000 lbs).

- One-hand operation for base clamp.

- System and sensor calibration services available.

- The AccuTEST offers a wide range of data reporting options and graphical output. Report formats include: test information, test results, valve data (with complete valve history), valve maintenance history and calibration.

- Test files stored permanently in computer for enhanced data management. Immediately track, access and print all information.