Pulsed Eddy Current Test

PEC

The application of PEC (Pipe and Equipment Condition) technology for insulated pressure vessels offers several significant advantages, especially in maintaining their integrity and operational efficiency. Here are some key points related to the use of PEC in this context:

1. Non-Intrusive Inspection:

PEC allows for the assessment of the condition of insulated pressure vessels without the need to remove insulation materials. This non-destructive testing method ensures that the insulation remains undisturbed while providing accurate data about the underlying metal.

2. Penetration Through Insulation:

The electromagnetic principles used in PEC enable it to penetrate various types of insulation materials, including those that are rough, wet, or heterogeneous. This capability is particularly beneficial for insulated pressure vessels, which often have complex insulation systems designed for thermal efficiency.

3. Detection of Corrosion and Anomalies:

PEC can effectively identify corrosion, pitting, and other structural anomalies in pressure vessels that may be hidden beneath insulation. Early detection of these issues is critical for maintenance and preventing failures due to pressure vessel degradation.

4. Baseline and Periodic Monitoring:

Given its excellent repeatability, PEC is well-suited for establishing baseline conditions of insulated pressure vessels and conducting regular monitoring. This ongoing assessment helps track changes over time, ensuring that any deterioration is caught before it leads to significant safety issues or costly repairs.

5. Rapid Inspection:

PEC technology can provide quick results compared to traditional methods that require time-consuming inspections and often involve insulation removal. This speed is especially advantageous for industries that require continuous operation and cannot afford lengthy downtimes.

6. Enhanced Safety:

Using PEC for inspections of insulated pressure vessels enhances safety by minimizing the risk associated with traditional inspection methods that may involve invasive techniques or temperature exposure. It allows for evaluations to be conducted with reduced disturbance to the operating environment.

Conclusion

In summary, PEC technology serves as an effective and efficient tool for assessing insulated pressure vessels. Its non-invasive nature, combined with the ability to penetrate various insulation types and detect structural issues, makes it invaluable in maintaining the safety and integrity of these crucial industrial components. By implementing PEC inspections, organizations can ensure regulatory compliance, optimize maintenance schedules, and extend the lifespan of their insulated pressure vessels.

-

Pulsed Eddy Current Testing (PECT) is indeed an advanced non-destructive testing (NDT) technique with several advantages, particularly for assessing corrosion and degradation in metallic structures. Here are some key points about PECT and its applications:

- Through-Coating Inspection: One of the significant advantages of PECT is its ability to inspect through non-conductive coatings such as paint, insulation, and various protective layers. This feature allows inspectors to assess the integrity of metallic substrates without the need to remove these coatings, saving time and cost associated with such preparatory work.

- Detection of Corrosion and Erosion: PECT is adept at identifying areas affected by corrosion or erosion. It can pinpoint regions of metal loss, which are critical for maintaining the structural integrity of components like pipelines, tanks, and storage vessels.

- Material Degradation Assessment: Beyond corrosion and erosion, PECT can assess other forms of material degradation. This includes uniform material loss and damage due to environmental factors or operational stresses.

- Use in Complex Geometries: The flexible application of PECT makes it useful for inspecting components with complex geometries or hard-to-reach areas, making it ideal for in-service inspections.

- Rapid and Cost-Effective: Because PECT does not require coating removal and can be performed relatively quickly, it is a cost-effective solution for regular maintenance inspections, reducing downtime in industrial processes.

- Data Analysis and Interpretation: PECT provides quantitative measurements, which can be analyzed to determine the extent of degradation. The results can guide maintenance decisions and the prioritization of repairs.

- Safety: Since PECT is a non-intrusive method, it enhances safety by minimizing the need for direct contact with hazardous materials or environments.

- depth down to two thousands meters

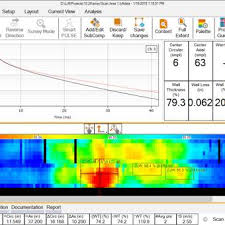

Reporting on Average Wall Thickness Screening and Detection of General Corrosion

Introduction

This report summarizes the findings from the average wall thickness screening of insulated pressure vessels and the detection of general corrosion using PEC (Pipe and Equipment Condition) technology. This methodology involves mapping the vessels according to a predetermined grid pattern to ensure comprehensive coverage and accurate assessment of wall integrity.

Methodology

-

Grid Mapping:

- The pressure vessel surface was divided into a grid pattern to facilitate systematic data collection.

- Each grid section was assigned a unique identifier for accurate reporting and tracking of measurements.

-

Average Wall Thickness Screening:

- PEC technology was employed to measure the thickness of the vessel walls at selected points within the grid.

- Measurements were taken both at ambient temperature and, where feasible, at the operational temperature to ensure consistency and reliability of data.

-

Detection of General Corrosion:

- The PEC method was utilized to identify areas of wall thinning indicative of general corrosion.

- Data collected from each grid point was analyzed to determine the presence and extent of corrosion or other anomalies in the wall structure.

Findings

-

Wall Thickness Measurements:

- The average wall thickness across the vessel was calculated based on the grid data.

- The measurements revealed variations in thickness that may suggest localized corrosion or wear.

-

Corrosion Detection:

- Several areas within the vessel were identified with significant wall thinning, indicating the presence of general corrosion.

- Specific grid sections were marked for further investigation, maintenance, or repairs based on the severity of corrosion detected.

-

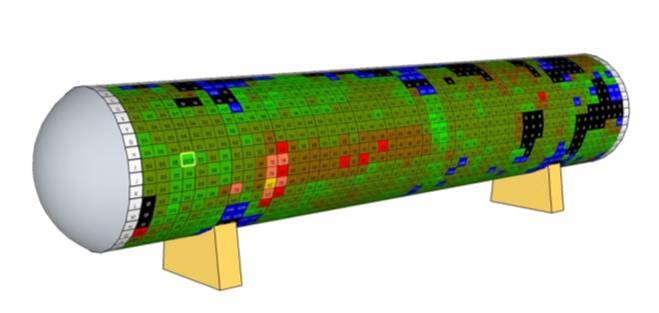

Visual and Data Mapping:

- The results were documented in a visual format, highlighting the mapped grid sections with color coding to indicate areas of concern (e.g., green for normal thickness, yellow for moderate corrosion, red for significant corrosion).

- A comprehensive report including graphs and tables was generated to present average wall thickness variations and locations of detected corrosion.

Recommendations

- Based on the average wall thickness screening and corrosion detection findings, it is recommended to:

- Prioritize inspection and maintenance of the areas with significant wall thinning.

- Schedule regular PEC inspections to monitor changes in wall thickness over time, facilitating early detection of any further corrosion developments.

- Consider protective measures such as coatings or corrosion inhibitors in areas prone to deterioration.

Conclusion

The implementation of PEC technology for average wall thickness screening and corrosion detection proves to be an essential practice for maintaining the integrity of insulated pressure vessels. Systematic grid mapping not only optimizes inspection processes but also enhances safety and operational reliability by allowing for targeted maintenance actions based on precise data. Future inspections should continue to incorporate these methodologies to ensure ongoing compliance and safety standards.

Advantages

PEC (Pipe and Equipment Condition) technology offers several advantages for inspecting and assessing the health of various industrial assets, particularly ferrous pipes and vessels. Here are some key benefits:

1. Non-Destructive Testing:

PEC is a non-invasive method that allows for the evaluation of materials without damaging or disturbing insulation and coatings. This feature eliminates the need for costly repairs or replacements of insulation materials.

2. Versatility with Insulation:

PEC can effectively assess the condition of ferrous pipes and vessels even when covered with thermal insulation, regardless of its condition (e.g., wet, rough, irregular). This versatility makes it suitable for a wide range of operational environments.

3. Accuracy and Precision:

PEC provides highly accurate and reliable measurements of wall thickness and integrity. By using advanced electromagnetic techniques, it can detect minor changes in material conditions, such as corrosion or pitting, that may not be visible through other inspection methods.

4. Rapid Inspection:

The technology facilitates faster inspections compared to traditional methods that often require more extensive preparations and potential shutdowns. This efficiency minimizes downtime and allows for quicker assessments.

5. Excellent Repeatability:

PEC offers consistent and repeatable results, which are essential for baseline assessments and ongoing monitoring. This allows for effective trend analysis over time, aiding in proactive maintenance decisions.

6. Safety Enhancement:

By conducting inspections without physical disruptions, PEC minimizes risks associated with entering confined spaces or working around hazardous materials. It enhances workplace safety for maintenance and inspection personnel.

7. Baseline Data Establishment:

PEC is ideal for establishing baseline measurements for equipment condition, providing a reference point for future inspections. This helps organizations track deterioration or changes over time effectively.

8. Cost-Effective:

Given its non-destructive nature and the reduction of downtime, PEC can be more cost-effective in the long run. Early detection of potential issues leads to timely maintenance, preventing expensive repairs or catastrophic failures.

9. Adaptability:

PEC can be adapted to a variety of applications and environments, making it suitable for different industries, including oil and gas, power generation, chemical processing, and more. It can handle various materials and conditions effectively.

10. Data Documentation:

The technology facilitates thorough documentation of inspections and findings, producing easy-to-read reports and visual representations of data. This documentation is valuable for regulatory compliance and internal audits.

Conclusion

Overall, PEC technology is a powerful tool for ensuring the integrity and safety of ferrous pipes and vessels. Its non-destructive nature, accuracy, and adaptability position it as a leading choice for industrial inspections and maintenance strategies.

Applications of PEC

-

Corrosion Under Insulation (CUI):PEC is effective in identifying and assessing CUI in insulated piping and vessels. It can detect corrosion that develops in areas where insulation creates conditions conducive to moisture accumulation.

-

-

Insulated Piping:

- Used to monitor the condition of insulated pipelines, PEC can measure wall thickness and locate areas of corrosion without requiring insulation removal, ensuring continuous operation.

-

Insulated Vessels:

- PEC technology assesses the integrity of insulated pressure vessels, providing accurate measurements of wall thickness and detecting any signs of corrosion.

-

Insulated Tanks:

- Insulated storage tanks can be inspected for corrosion and wall integrity using PEC, especially in environments where liquid contents can lead to corrosion beneath insulation.

-

High-Temperature Applications:

- PEC is suitable for high-temperature applications, allowing for inspections during operational conditions to detect material degradation in steel components.

-

Composite Wrap Repaired Areas:

- Inspections of areas that have been repaired with composite wraps can be conducted using PEC to ensure that the repairs are holding up and that the underlying material remains sound.

-

Concrete Coated Pipes:

- PEC allows for the inspection of pipes coated with concrete, helping to detect any corrosion that may be occurring underneath the coating without the need for extensive excavation.

-

Power Plant Piping:

- In power plants, PEC is utilized to monitor piping systems for signs of corrosion and integrity, helping maintain safe and efficient operations.

-

Flow Accelerated Corrosion (FAC):

- PEC can detect FAC, which occurs due to high-velocity flow causing erosion and thinning of pipe walls, particularly in areas susceptible to water hammer.

-

Behind Concrete Fireproofing:

- Inspections behind concrete fireproofing materials can be conducted effectively, allowing for the detection of corrosion on structural components that are otherwise difficult to assess.

-

Vessel Skirts:

- PEC technology can assess the condition of vessel skirts, ensuring that the supporting structures are sound and free from corrosion.

-

Boilers:

- Regular inspections of boiler components can be performed to monitor for any corrosion or deterioration, ensuring operational efficiency and safety.

-

Sphere Legs:

- The legs of spherical storage tanks can be inspected for corrosion using PEC, providing critical information about structural integrity.

-

Surfaces Covered by Marine Growth:

- PEC is useful in assessing the condition of submerged surfaces, particularly in marine environments where growth can obscure visual inspections.

-

Offshore Risers:

- Inspections of offshore riser pipes, which transport oil and gas from the seabed to surface installations, can be conducted to monitor for corrosion and structural integrity.

-

Caissons:

- PEC can be used for the evaluation of caissons, which are often submerged and can be subject to corrosion due to seawater exposure.

-

Port Structures and Steel Sheet Piling:

- Integrity assessments of various port structures and steel sheet piling can be performed using PEC technology to ensure safety and stability.

-

Ship Hulls:

- The hulls of ships can be inspected for corrosion and material integrity beneath marine growth or coatings, ensuring the safety of vessels in navigable waters.

-

Subsea Pipelines:

- PEC is applicable for assessing subsea pipelines for corrosion, allowing for long-term monitoring of these critical infrastructure components.

Conclusion

PEC technology is highly versatile and plays a crucial role in the safe and effective monitoring of various industrial structures and applications. Its ability to detect corrosion, maintain integrity assessments, and operate without disrupting insulation makes it an invaluable tool across multiple sectors, especially in environments where traditional inspection methods are less feasible.